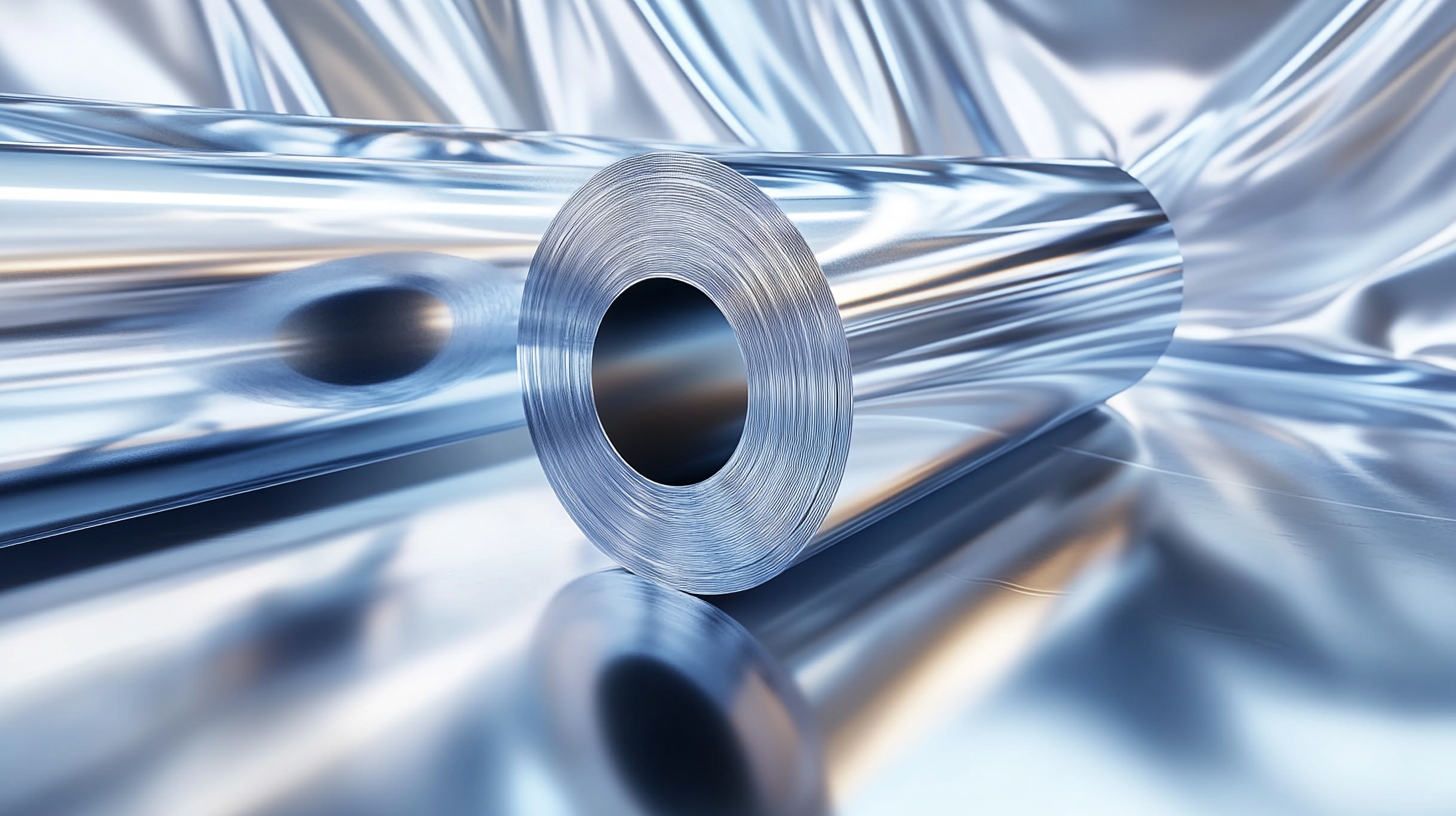

Understanding the Challenges in Sourcing the Best Aluminum Foil Sealing Film for Global Markets

In recent years, the global market for Aluminum Foil Sealing Film has witnessed significant growth, driven by increasing demand across various sectors such as food packaging, pharmaceuticals, and consumer goods. According to a report by MarketsandMarkets, the aluminum foil market is projected to reach USD 33 billion by 2025, with a notable compound annual growth rate (CAGR) of approximately 4.7%. However, sourcing the best Aluminum Foil Sealing Film poses several challenges, including fluctuating raw material prices, stringent regulatory requirements, and the need for sustainable packaging solutions. As industries strive to balance cost-effectiveness with environmental considerations, understanding the intricacies of sourcing this essential packaging material becomes critical for enterprises aiming to compete in the global market. This blog will delve into these challenges and provide insights on navigating them effectively.

Identifying Key Properties of Aluminum Foil Sealing Films for Diverse Applications

When sourcing aluminum foil sealing films for global markets, understanding the key properties essential for diverse applications is crucial. Aluminum foil is valued for its barrier properties, which significantly affect product shelf life and integrity. According to a report by Smithers Pira, the global market for aluminum foil packaging reached approximately $30 billion in 2021, with a projected CAGR of 4.2% through 2026. This growth underscores the demand for films that offer excellent moisture, light, and oxygen barriers, which are essential for food, pharmaceuticals, and consumer goods.

Furthermore, the thickness and seal strength of aluminum foil sealing films play a vital role in their performance. Industry standards typically recommend gauges of 20-50 microns for varying applications, with heavier films used for products requiring more robust protection. Additionally, the inclusion of other materials, such as polymers, can enhance heat sealability, making the films suitable for high-speed automated packaging systems. As highlighted in a recent study by Grand View Research, the development of multi-layer films that incorporate aluminum foil is gaining traction, providing customizable solutions for specific market needs and improving overall product quality. Understanding these key properties and their implications is essential for manufacturers looking to meet the evolving demands of the global market.

Understanding the Challenges in Sourcing the Best Aluminum Foil Sealing Film for Global Markets

| Property |

Description |

Importance |

Application Areas |

| Thickness |

Usually measured in microns; impacts barrier properties and strength. |

Critical for sealing effectiveness and product protection. |

Food packaging, pharmaceutical packaging. |

| Sealing Temperature |

The temperature at which the sealing film effectively adheres to the substrate. |

Affects production speed and sealing integrity. |

Dairy products, ready-to-eat meals. |

| Barrier Properties |

Resistance to moisture, gases, and light. |

Essential for prolonging shelf life of products. |

Snack foods, beverages, cosmetics. |

| Transparency |

Degree to which the film allows light to pass through. |

Important for product visibility and appeal. |

Consumer goods packaging, retail products. |

| Printability |

Ability to print designs and branding on the surface. |

Affects marketing and brand recognition. |

All consumer product packaging that requires branding. |

Evaluating Supplier Credentials: What to Look for in Aluminum Foil Distributors

When sourcing aluminum foil sealing film for global markets, evaluating supplier credentials is essential to ensure quality and reliability. First and foremost, check for industry certifications that demonstrate adherence to international quality standards. Certifications such as ISO 9001 indicate a commitment to quality management systems, while others like FDA approval are crucial, especially for food packaging applications. This validation of standards not only assures the safety of the products but also highlights the supplier's dedication to maintaining high production practices.

Additionally, it's important to assess the distributor's manufacturing capabilities and technological advancements. Suppliers with modern production facilities are more likely to offer cutting-edge materials that enhance functionality. Look for distributors who can provide detailed product specifications, including thickness, barrier properties, and ability to withstand various environmental conditions. A robust track record with existing clients and positive testimonials can further signify a supplier's credibility. Engaging with suppliers who prioritize transparency and open communication is vital for building a successful partnership in sourcing aluminum foil sealing film.

Understanding Global Compliance Standards for Aluminum Foil Sealing Products

The demand for aluminum foil sealing products is at an all-time high, especially in the pharmaceutical sector where compliance with global standards is critical. In the Global Pharmaceutical Contract Packaging Market, which is projected to reach USD 34.80 billion by 2034, there is an increasing focus on ensuring that packaging materials, including aluminum foil sealing film, adhere to stringent regulations and compliance standards. These standards guarantee product safety and efficacy, which are paramount in a highly regulated industry.

Moreover, the pharmaceutical tamper-proof packaging market is estimated to grow at a CAGR of over 6.4% from 2025 to 2034, predominantly driven by the need for secure and compliant packaging solutions. As manufacturers seek to navigate these compliance standards, the selection of materials becomes vital. For instance, aluminum foil is favored not only for its barrier properties but also for its ability to meet various government regulations.

Understanding these global compliance standards is essential for companies looking to compete effectively and sustainably in the marketplace.

Strategies for Building Long-Term Relationships with Suppliers in the Foil Industry

Building long-term relationships with suppliers in the foil industry is essential for companies looking to thrive in the competitive global market. Consistent communication is one of the key strategies to foster trust and reliability. Regular check-ins and updates can help both parties address challenges proactively, ensuring that production schedules align with supply capabilities.

Building long-term relationships with suppliers in the foil industry is essential for companies looking to thrive in the competitive global market. Consistent communication is one of the key strategies to foster trust and reliability. Regular check-ins and updates can help both parties address challenges proactively, ensuring that production schedules align with supply capabilities.

Tips: Always prioritize transparency when discussing projections and potential issues. This openness not only strengthens relationships but also encourages collaboration in problem-solving.

Additionally, investing time in understanding your supplier's capabilities and challenges can significantly enhance your partnership. By conducting site visits and audits, you can gain insight into their operations, leading to better coordination and innovation opportunities.

Tips: Look for opportunities to support your suppliers in overcoming obstacles. By offering assistance, whether through shared resources or joint training initiatives, you can cultivate a more resilient supply chain together.

Cost vs. Quality: Making Informed Decisions When Sourcing Sealing Films

When sourcing aluminum foil sealing films for global markets, organizations face a pivotal decision: balancing cost versus quality. In today's competitive landscape, it is essential to recognize that the lowest price may not always deliver the best value. High-quality sealing films are crucial for maintaining product integrity, extending shelf life, and ensuring compliance with safety regulations.

Investing in superior materials can result in long-term savings by reducing product spoilage and enhancing consumer trust.

Moreover, understanding the specific needs of your market is vital. Different industries, such as food packaging and pharmaceuticals, have unique requirements that may demand higher-quality films. Conducting a thorough analysis of your supply chain can help identify the right balance between cost and quality, ensuring you select a sealing film that meets both your performance criteria and budget constraints.

By making informed decisions, companies can find a sealing film that not only minimizes risks but also helps build a strong brand reputation in a global marketplace.